Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-09-10 Origin: Site

In modern industry, efficiency is a key factor in achieving productivity, quality, and cost-effectiveness. Cleaning and surface preparation are critical steps in many manufacturing, maintenance, and restoration processes, but traditional methods—such as mechanical scraping, sandblasting, or chemical cleaning—often come with limitations. These methods can be labor-intensive, time-consuming, potentially damaging to materials, and environmentally hazardous.

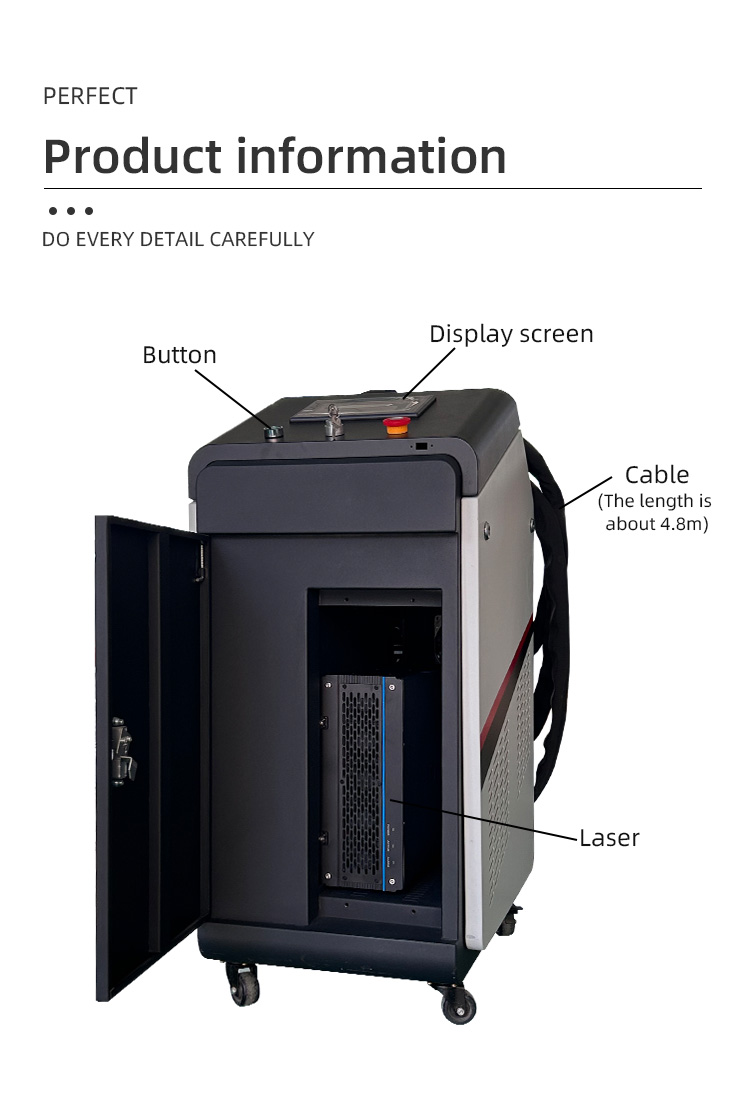

Portable laser cleaning machines have emerged as a transformative solution, offering precision, speed, and adaptability for a wide range of industrial applications. Unlike stationary laser systems, portable models provide the flexibility to clean surfaces on-site, reaching complex or large structures that are difficult to transport. By combining portability with the advantages of laser technology, these machines enhance operational efficiency, reduce labor and downtime, and improve product quality.

This article explores how portable laser cleaning machines work, their key benefits, and the ways they are enhancing efficiency across various industries.

Portable laser cleaning machines operate using high-intensity laser pulses to remove contaminants from surfaces. The process relies on laser ablation, where the energy from the laser is absorbed by dirt, rust, paint, or oxide layers, causing them to vaporize or detach while leaving the underlying substrate intact.

The typical workflow includes:

Emission of Laser Pulses: The machine emits controlled pulses of laser light with precise energy levels and durations.

Contaminant Interaction: The contaminant absorbs the laser energy more rapidly than the base material, leading to its removal.

Clean Surface Outcome: The unwanted layer is vaporized or dislodged, leaving a clean, smooth surface ready for subsequent processing, coating, or inspection.

Portable machines maintain the same precision as larger stationary systems but offer the advantage of mobility. Their compact design allows operators to easily transport the device to different sites, reach vertical or confined surfaces, and perform cleaning tasks without dismantling large equipment.

Non-Contact Cleaning: One of the most significant benefits of laser cleaning is that it is non-contact. Unlike mechanical methods, it does not scratch, deform, or damage the surface. This ensures that delicate components and critical structures remain intact during cleaning.

Time Efficiency: Portable laser cleaning machines dramatically reduce cleaning time. Traditional mechanical or chemical methods often involve multiple steps, preparation, and extensive labor. Laser cleaning provides a fast, single-step solution, allowing operators to complete tasks efficiently and increase productivity.

On-Site Flexibility: The portability of these machines allows cleaning to occur wherever it is needed. Large or immovable components, industrial machinery, or infrastructure can be cleaned without disassembly or transport, saving both time and logistics costs.

Environmentally Friendly: Portable laser cleaning eliminates the need for chemicals, abrasive media, or solvents, reducing environmental impact and workplace hazards. Vaporized contaminants can be safely collected using fume extraction systems.

Precision and Control: Laser cleaning is highly controllable, removing only the contaminant layer without affecting the substrate. This is especially important in industries where material integrity and surface quality are critical, such as aerospace, electronics, and precision engineering.

Reduced Labor Costs: Because the cleaning process is automated and requires less manual effort, labor costs are lower compared to traditional methods. Operators can focus on supervising and guiding the machine rather than performing intensive physical cleaning.

Portable laser cleaning machines are versatile tools used across a wide range of industries to enhance operational efficiency and product quality.

Metal Fabrication: In metalworking, surfaces often require cleaning from rust, scale, or oxide layers before welding, coating, or painting. Portable laser cleaning machines allow operators to prepare large metal sheets, pipes, and structural components efficiently on-site, improving adhesion and reducing rework.

Automotive Industry: Automotive repair shops and manufacturers benefit from portable laser cleaning when restoring vehicle components. Paint, rust, and grease can be removed quickly and precisely without damaging underlying metal or composite parts, reducing repair time and improving finish quality.

Aerospace and Aviation: Aircraft components, including turbine blades, fuselage panels, and landing gear, require high-quality surface preparation. Portable laser cleaning machines allow for on-site maintenance without disassembling large structures, enhancing operational efficiency while maintaining safety and material integrity.

Electronics and Semiconductor: Electronic components are highly sensitive, and contamination can cause malfunctions. Portable laser cleaning removes flux residues, oxidation, and fine particles without physical contact, preventing damage and ensuring consistent performance.

Energy Industry: Turbines, wind generators, and power plant equipment benefit from on-site laser cleaning. Removing scale, corrosion, or coatings without dismantling large machinery reduces downtime and ensures efficient operation.

Cultural Heritage and Restoration: Historical artifacts and monuments often require gentle, precise cleaning. Portable laser cleaning machines allow conservators to safely remove dirt, corrosion, and unwanted coatings without harming delicate surfaces, preserving the authenticity of the materials.

The portability and speed of laser cleaning machines directly impact industrial productivity. Tasks that once required hours or days can now be completed in a fraction of the time, reducing production bottlenecks.

Minimized Downtime: In industries such as aerospace, automotive, and energy, machine downtime can be costly. Portable laser cleaning enables rapid on-site surface preparation, minimizing operational interruptions.

Simplified Logistics: Moving heavy or large components to a cleaning facility is often expensive and time-consuming. Portable machines eliminate this step, allowing maintenance to occur wherever the equipment is located.

Consistent Results: Traditional methods often rely on manual labor, which can introduce variability. Laser cleaning provides repeatable, high-quality results, ensuring uniform surface preparation across components.

Reduced Material Waste: Because laser cleaning is non-contact and precise, there is minimal risk of substrate damage. This reduces scrap rates, repair needs, and associated costs, further improving operational efficiency.

While laser cleaning is safer than chemical or abrasive methods, proper precautions are essential. Operators should use protective eyewear to shield against laser exposure and ensure adequate ventilation or fume extraction to handle vaporized contaminants.

By eliminating chemicals and abrasives, portable laser cleaning reduces the risk of skin irritation, respiratory hazards, and environmental pollution. It also avoids secondary waste generated by sandblasting or chemical cleaning, contributing to cleaner, more sustainable industrial practices.

Although portable laser cleaning machines require an initial investment, they offer substantial long-term cost savings:

Labor Savings: Reduced manual effort and faster cleaning times decrease labor expenses.

Lower Material Costs: No need for solvents, chemicals, or abrasive media.

Reduced Rework and Waste: Non-contact cleaning preserves material integrity, reducing repair and replacement costs.

Maintenance Efficiency: On-site cleaning eliminates downtime associated with transporting equipment for cleaning.

These savings, combined with increased productivity and quality, make portable laser cleaning machines a smart investment for industries seeking both efficiency and sustainability.

As industries demand higher productivity, precision, and sustainability, portable laser cleaning machines are expected to play an increasingly prominent role. Advances in laser technology, automation, and machine portability continue to expand the range of applications and capabilities.

Emerging models integrate robotics, remote operation, and real-time monitoring to further enhance efficiency. Portable laser cleaning machines are no longer limited to small components; they can handle larger structures, complex geometries, and sensitive materials with minimal intervention.

The growing emphasis on sustainable industrial practices also drives adoption, as portable laser cleaning eliminates hazardous chemicals, reduces waste, and minimizes energy consumption compared to traditional methods.

Portable laser cleaning machines are transforming industrial surface preparation by providing fast, precise, and environmentally friendly cleaning solutions. Their portability allows for on-site operation, reducing downtime, labor costs, and logistical challenges, while their precision ensures that surfaces are prepared without damaging underlying materials.

From metal fabrication and automotive repair to aerospace, electronics, energy, and cultural restoration, portable laser cleaning machines enhance efficiency, productivity, and quality across industries. By simplifying processes, supporting sustainability, and delivering consistent results, these machines represent a forward-thinking solution for modern industrial needs.

As industries continue to prioritize operational efficiency, safety, and environmental responsibility, portable laser cleaning machines offer a reliable, versatile, and cost-effective tool that meets the demands of today’s dynamic industrial landscape.